Crack Repair 101

As always, the severity and persistence of each blustering winter becomes apparent in the damage it leaves behind. True of many things, and particularly evident in the state of our Spring asphalt.

As always, the severity and persistence of each blustering winter becomes apparent in the damage it leaves behind. True of many things, and particularly evident in the state of our Spring asphalt.

This month, we thought we could be of the most help to our readers by sharing some crack repair knowledge, answering the questions we get asked most often, and making some recommendations.

“Do I need a crack filler or a crack sealer?” That depends on if the cracks you are repairing are what we call “working” or “non-working”. Working cracks experience significant movement in any direction. Transverse cracks, the ones you see that are perpendicular to the centre line, are a good example of these. Rubberized sealer is a good solution for working cracks because of it’s flexibility. It will bind to the existing pavement and minimize moisture penetration even as shift occurs. Filler is a great solution for non-working cracks (do not experience movement), such as longitudinal or alligator cracks. By filling the crack (deeper than a sealer) it provides support for the existing asphalt while also minimizing moisture penetration. The filler will last because the crack is not experiencing significant movement.

“How can I prevent product from coming out of the crack or being scraped out by a plow?” The key to long-lasting repair is application. The best time to repair cracks is in cooler Spring temperatures (just above 10 degrees) because the space between cracks will expand and contract with the temperature. If you fill or seal a crack in summer when temperatures are hot, the crack is at it’s narrowest and when temperatures cool down the product will not be enough to effectively fill or seal it at it’s widest. The same goes for filling or sealing when the temperature is too cold. Firstly, the product may not cure correctly, and secondly, too much product will be applied and it will be squished by the expanding pavement when temperatures heat up making it heave out of the crack. Any application error that causes the fill to not sit flush with the road will leave the fill vulnerable to being ripped out by snow plows, other equipment, or traffic.

“Why is your product better than something from Canadian Tire?” Products being sold in retailers often spend a good amount of time in storage and sitting on the shelf, and they are actually developed with this in mind. A long shelf life is achieved by having a relatively low solids content to keep the product workable for longer. The solids content is the material you are left with once all the water evaporates, AKA the stuff you’re paying for. Having a low solids content means that the product will take longer to set up or cure, leaving it vulnerable for longer, and making it more prone to deficiencies. Western Asphalt’s products were engineered for the use of our contracting division, West-Can Seal Coating. This means that they were developed for immediate use and to meet the high standards set by the government agencies we work with. In comparing WAP’s CA-90 Cold Pour Crack Filler with a popular cold pour crack filler found at a retailer, CA-90 was found to have > 35% higher solids content. The consumer grade product was only 15 – 25% asphalt content, compared to CA-90’s minimum 60%. Even more interestingly, when comparing equal quantities the consumer products retail price was 50% more! That’s some expensive H20!

More questions?

Send us a message.

June 04 2020

Western Asphalt Products proudly received AEMA Excellence in Manufacturing Award for exceeding AEMA requirements and best practices in regards to our environmental practices, general operations, and safety within our laboratory and manufacturing plant.

Western Asphalt Products proudly received AEMA Excellence in Manufacturing Award for exceeding AEMA requirements and best practices in regards to our environmental practices, general operations, and safety within our laboratory and manufacturing plant.

Left: Pallets of bagged Western Pothole Repair sit in Western Asphalt’s yard in Brandon, MB

Right: A bulk pile of WPR in Bruderheim, AB

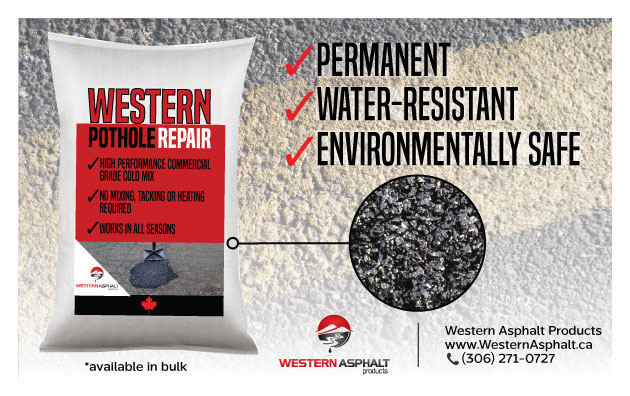

Western Asphalt Products recently started producing and bagging Western Pothole Patch. This high performance cold-mix is now available by the bag, pallet or in bulk and does not require mixing, tacking or heating, making it an easy and environmentally safe solution to your city or town’s pothole repair needs.

Left: Pallets of bagged Western Pothole Repair sit in Western Asphalt’s yard in Brandon, MB

Right: A bulk pile of WPR in Bruderheim, AB

Western Asphalt Products recently started producing and bagging Western Pothole Patch. This high performance cold-mix is now available by the bag, pallet or in bulk and does not require mixing, tacking or heating, making it an easy and environmentally safe solution to your city or town’s pothole repair needs.