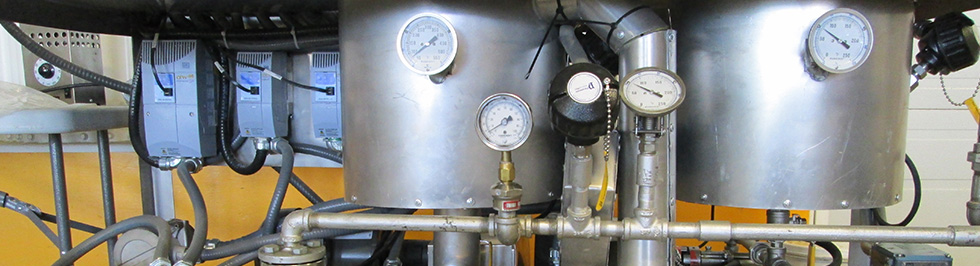

Western Asphalt Products’ materials testing laboratory is an AASHTO Accredited Laboratory operating in accordance with the quality management requirements as outlined in AASHTO R-18¹. With superior capabilities in the following sectors, Western Asphalt Products’ offers client access to comprehensive asphalt-binder, cutback asphalt, asphalt emulsion and aggregate testing services as well as Microsurfacing and Slurry Seal mix design formulation.

Western Asphalt’s laboratory is capable of performing all testing of asphalt emulsion or cutback asphalts as may be required by municipal, county, provincial or state specifications. The Laboratory also boasts capabilities in the testing of asphalt-binder and aggregate as used in road construction and maintenance projects. Western Asphalt’s Laboratory is capable of performing the following ASTM test procedures:

Note: All stated methods may also be performed to customer specifications using AASHTO, CGSB, ISO, or other provincial/state standards.

- Emulsified Asphalt

- ASTM D6930 – Settlement and Storage Stability

- ASTM D6933 – Sieve Test

- ASTM D6934 – Residue by Evaporation

- ASTM D6935 – Cement Mixing

- ASTM D6936 – Demulsibility

- ASTM D6997 – Residue by Distillation

- ASTM D6998 – Aggregate Coating

- ASTM D7496 – Saybolt Viscosity at 25°C and 50°C

- Asphalt Binder

- ASTM D5 – Penetration of Bituminous Materials

- ASTM D36 – Softening Point of Bitumen (Ring-and-Ball)

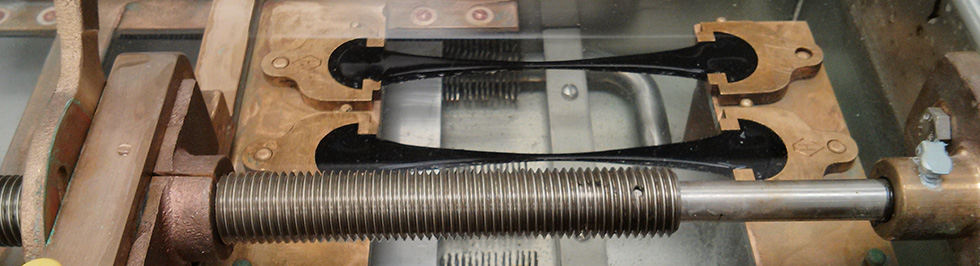

- ASTM D113 – Ductility of Bituminous Materials

- ASTM D139 – Float Test for Bituminous Materials

- ASTM D2042 – Solubility of Asphalt Materials in TCE

- ASTM D2170 – Kinematic Viscosity of Asphalts

- ASTM D2171 – Viscosity of Asphalts by Vacuum Capillary Viscometer

- ASTM D6084 – Elastic Recovery Test

- ASTM D92 – Flash Point by Cleveland Open Cup

- ASTM D402 – Distillation of Cutback Asphalts

- ASTM D4402 – Viscosity Determination with Rotational Viscometer

- Pavement Preservation

- ISSA TB-100 – Wet Track Abrasion of Slurry Surfacing Systems

- ISSA TB-109 – Excess Asphalt by Loaded Wheel and Sand Adhesion

- ISSA TB-113 – Determining Mix Time for Slurry Surfacing Systems

- ISSA TB-114 – Wet Stripping of Cured Slurry Surfacing Mixtures

- ISSA TB-139 – Set and Cure Development of Slurry by Cohesion Tester

- ISSA TB-144 – Classification of Micro-Surfacing Materials (SBR)

- ISSA TB-147 – Loaded Wheel Tester, Cold Mixes (LWT)

- Aggregate

- ASTM C117 – Materials Finer than 75μm in Aggregates

- ASTM C136 – Sieve Analysis of Aggregates

- ASTM D2419 – Sand Equivalent Test

- ASTM D3625 – Coating Test: Boiling

- ASTM D5821 – Fractured Particles in Coarse Aggregate

- Other Asphalt Binder Tests

- ASTM D562 – Krebs Viscosity Using a Stormer-Type Viscometer

- ASTM D5329 – Cone Penetration

- ASTM D5329 – Flow

- ASTM D5329 – Resilience

Western Asphalt Products understands that road construction and maintenance issues are as unique as their respective solutions. In light of this, Western Asphalt Products has immense capability in formulating tailored solutions unique to customer’s issues. Whatever properties you are after, allow our laboratory to formulate a tailored solution for your company. Western Asphalt Products is behind your goals.

Micro-Surfacing & Slurry Formulation

As Micro-Surfacing and Slurry Seal projects rely heavily on an intimate aggregate-emulsion compatibility, Western Asphalt Products formulates aggregate-specific mix-designs through the use of standards as outlined by the International Slurry Surfacing Association (ISSA). Western Asphalt Products is capable of performing the following mix design procedures:

- ISSA Technical Bulletin 100 – Wet Track Abrasion of Slurry Surfaces

- ISSA Technical Bulletin 106 – Measurement of Slurry Seal Consistency

- ISSA Technical Bulletin 109 – Measurement of Excess Asphalt in Bituminous Mixtures by Use of a Loaded Wheel Tester and Sand Adhesion

- ISSA Technical Bulletin 113 – Trial Mix Procedure for Slurry Design

- ISSA Technical Bulletin 114 – Wet Stripping Test for Cured Slurry Seal Mix

- ISSA Technical Bulletin 139 – Test Method to Classify Emulsified Asphalt/Aggregate Mixture Systems by Modified Cohesion Tester Measurement of Set and Cure Characteristics

- ISSA Technical Bulletin 144 – Classification of Aggregate Filler-Bitumen Compatability by Schulze-Breuer and Ruck Procedures

- ISSA Technical Bulletin 145 – Determination of Methylene Blue Adsorption Value (MBV) of Mineral Aggregate Fillers and Fines

- ISSA Technical Bulletin 147 – Measurement of Stability and Resistance to Compaction, Vertical and Lateral Displacement of Multilayered Fine Aggregate Cold Mixes

Western Asphalt’s Laboratory would be happy to produce a micro-surfacing or slurry mix design for your company. Please contact us for details.

Technical Director

Western Asphalt Products 65 Limestone Road East Brandon, MB R7A 7L5